PRODUCT & PROCESS VALIDATION

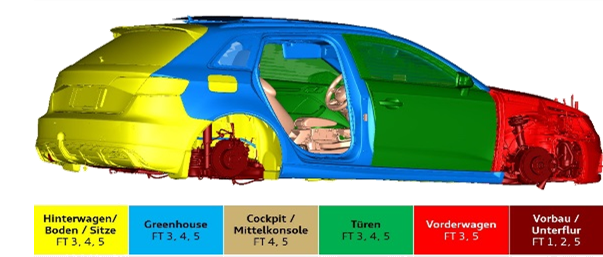

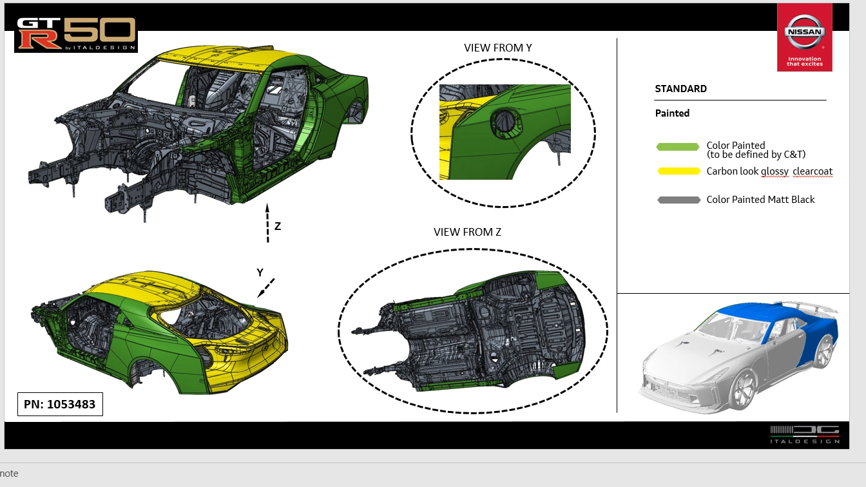

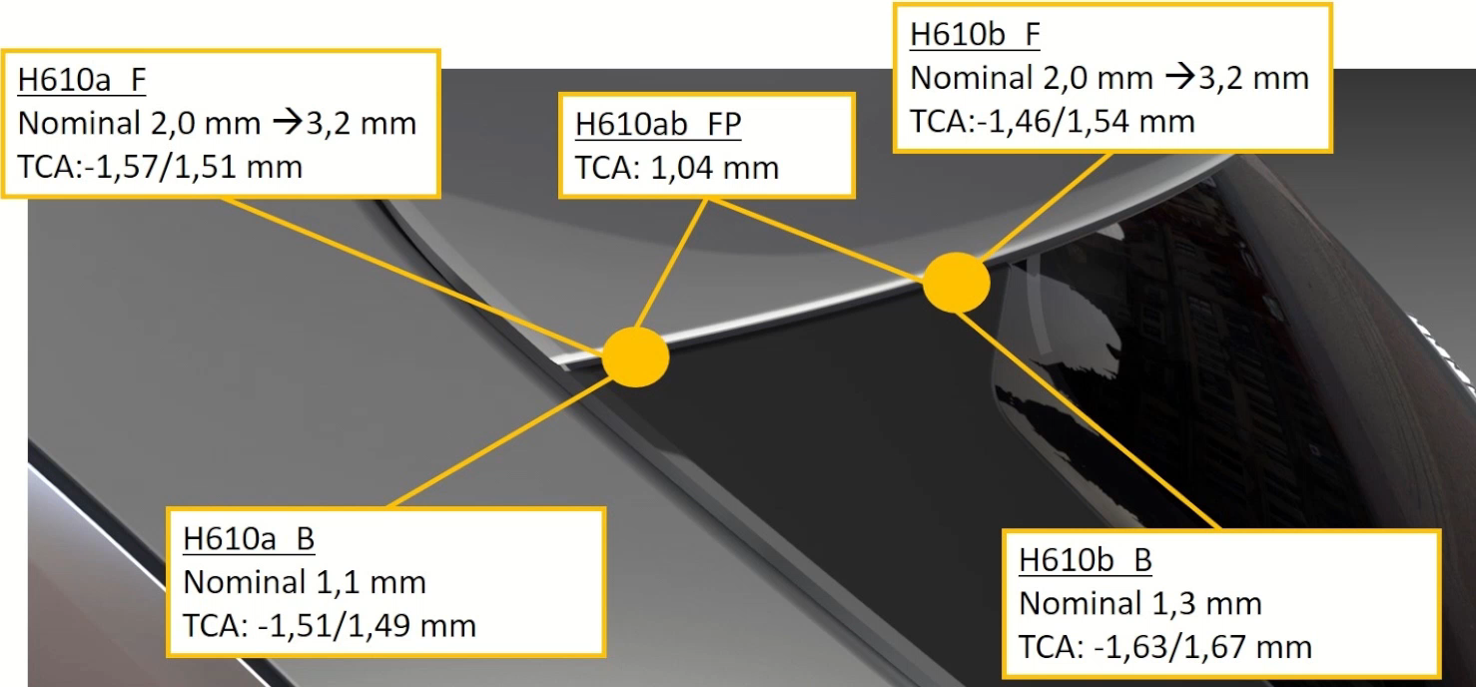

Quality, proper sequence, conformity, tolerance chain do converge and synergistically work to start a producible assembly.

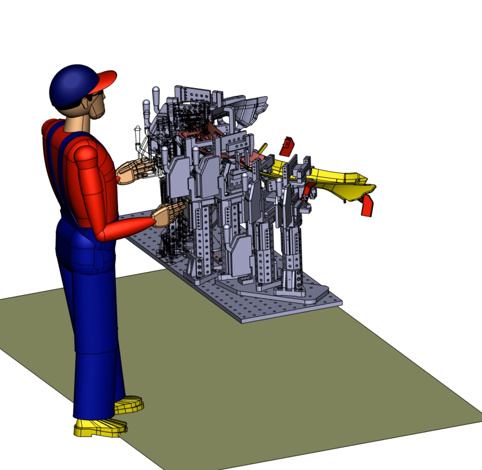

As a first step, verifications are set-up virtually: simulations include the complete assembly and the feasibility assessment to avoid critical issues occurring in maintenance and assistance.

Geometric check, assembly sequence definitions and check, assembly check, J&F prototype engineering, RPS definitions and tolerance chain control, assembly sheet documentations, assembly simulations in virtual reality: all this is daily managed and fully integrated in the development process.

Time and costs are thus optimized and kept under control.